0086-535-8618899

0086-535-8618899

- PS Foam Sheet Extrusion Line

- Product brand::Haiyuan

- whatsapp/wechat::Amy 008613573511028

- whatsapp/wechat::Ellie 008613780912769

- E-mail: admin@ythaiyuan.com/manager@ythaiyuan.com

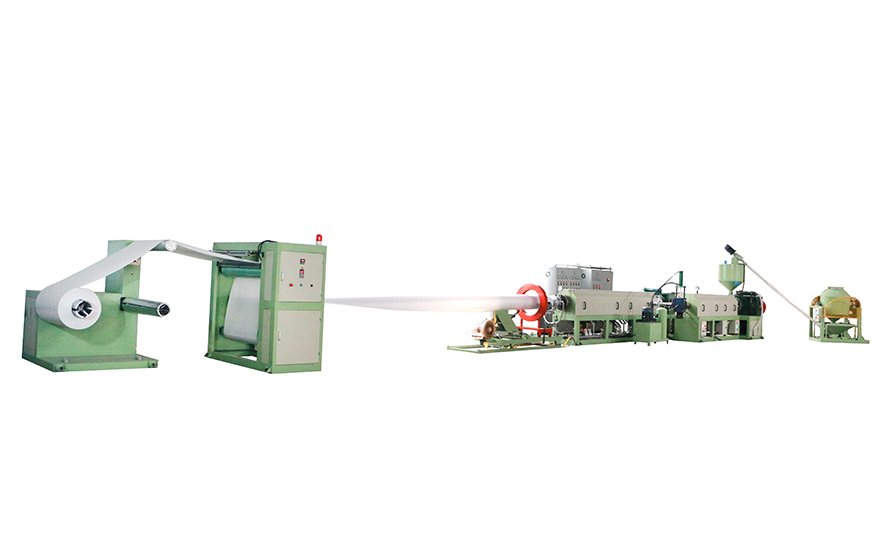

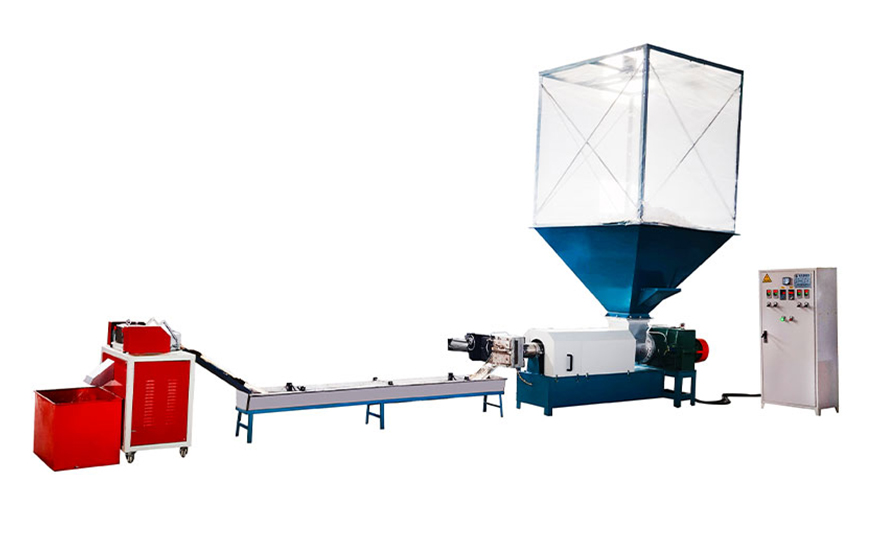

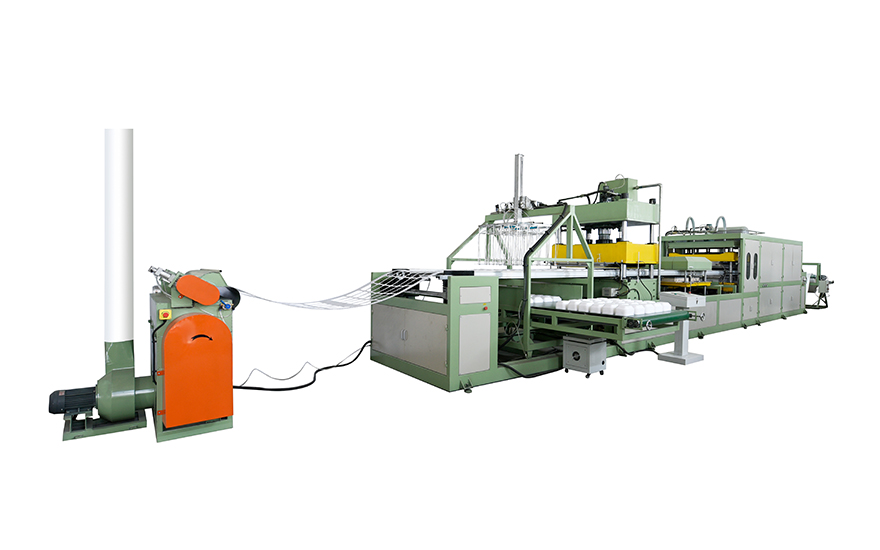

PS Foam Sheet Extrusion Line adopts Gentian type double-stage series high foam technology. The raw material is general polystyrene granule. In the extruding process, vesicant is injected at high pressure. After extruding, foaming cooling, shaping and hauling off, it is winding to finished ps foam sheet rolls .After vacuum forming system, the finished PS foaming sheet can be made into variety of packaging vessels such as fast food box, aquatic plate, supermarket tray, cake tray ,KT board, instant noodle bowl, foam tray etc. It is widely used in the packing of food, fruit advertising ,industrial products and so on. This equipment adopts high speed non-stop hydraulic filter changer and PLC controller, advantages as advanced structure, stable performance, easy operation and high quality.

Model

Parameter

Unit

HY-75/90

HY-105/120

HY-110/130

HY-135/150

Capacity

kg/h

80-100

200-240

230-260

280-360

Sheet thickness

mm

1--4

1--4

1.5--5

2--5

Sheet width

mm

640-1080

640-1080

800-1080

900-1080

Foaming rate

10--22

Cooling method

wind&water cooling

Cutting method

single cutting

Butagas pressure

Mpa

0.9-1.2

Installation power

kw

160

200

260

320

Installation Dimension

m

24x6x3

30x6x3

32x6x3

35x8x3

Power supply

3 Phase 380V 50HZ 3Phase 220V 60HZ

- Amy:whatsapp/wechat:008613573511028

- Tel:0086-535-8618899

- Ellie:whatsapp/wechat: 008613780912769

- Fax:0086-535-8662211

- E-mail:manager@ythaiyuan.com

- E-mail:admin@ythaiyuan.com

- Add:Lvjie Road 90, High-Tech Industrial Park , Longkou City,Shandong Province , China